Advantages/Properties

- CCS Belt Take-ups are fully-enclosed belt tensioning systems

- Robust design for durability in the harshest conditions

- ACME threaded rods standard on all units

- Available in painted carbon steel or stainless steel

- Wide range of sizes for all industries

- Several standard models available for immediate shipment

- Keep belts constantly tensioned and tracked

- Easy to install

- Low Maintenance

- Threaded rods offer easier adjustment and extended unit life

- Totally enclosed construction for protection from contaminents

Take-Up Styles |

|

|

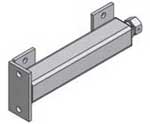

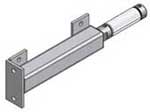

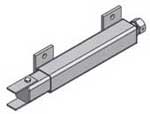

Basic Made up of two telescoping tubes that fully enclose a threaded adjustment rod. ACME thread and pinned hex nuts are standard on all units to provide faster, easier adjustment. |

|

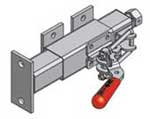

Quick Release Allow easy movement of the telescoping tubes for washdown purposes. As the clamp is released, the original take-up adjustments remain unchanged providing a time saving option. |

|

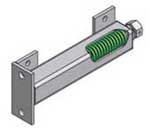

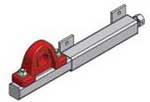

Spring Compression Provide constant belt tension–reducing adjustment needs. |

|

Linear Actuator Feature either a hydraulic or pneumatic cylinder mounted to the rear. Hydraulic models are for heavy-duty use, while pneumatic models are for lighter applications. These take-ups are equipped to balance adjustment of both units simultaneously. |

Take-Up Mounting Options |

|

|

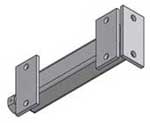

Plates Consists of two mounting plates drilled for four bolt mounting. All CCS Take-Ups include standard mounting plates unless otherwise specified. |

|

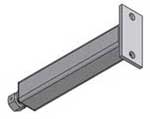

Welded This option does not include any plates or studs. The unit is meant to be mounted directly to the conveyor frame. |

|

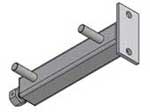

Studs Studs are welded to the inside face of the units allowing quick and easy mounting. This style provides a smaller vertical profile |

|

Motorized Pulley Accommodates all sizes of motorized pulleys. Specifically fabricated for each shaft size. Mounting is made easy with the bolt-on top plate. |

|

Top Mount Designed for a pillow block bearing mounted to the top of the inner tube. Inner tube is extended the length of the pillow block base to provide the same take-up ranges as the basic model. |

Click to view larger |

Standard Take-Up Dimensions

|

Tapped Base Pillow Block Dimensions

|

Pillow Block Dimensions

|

Don't see what you need? We'll be happy to design any of our products to meet your specific needs.

Call a CCS Sales Representative today at (865) 777-1096.